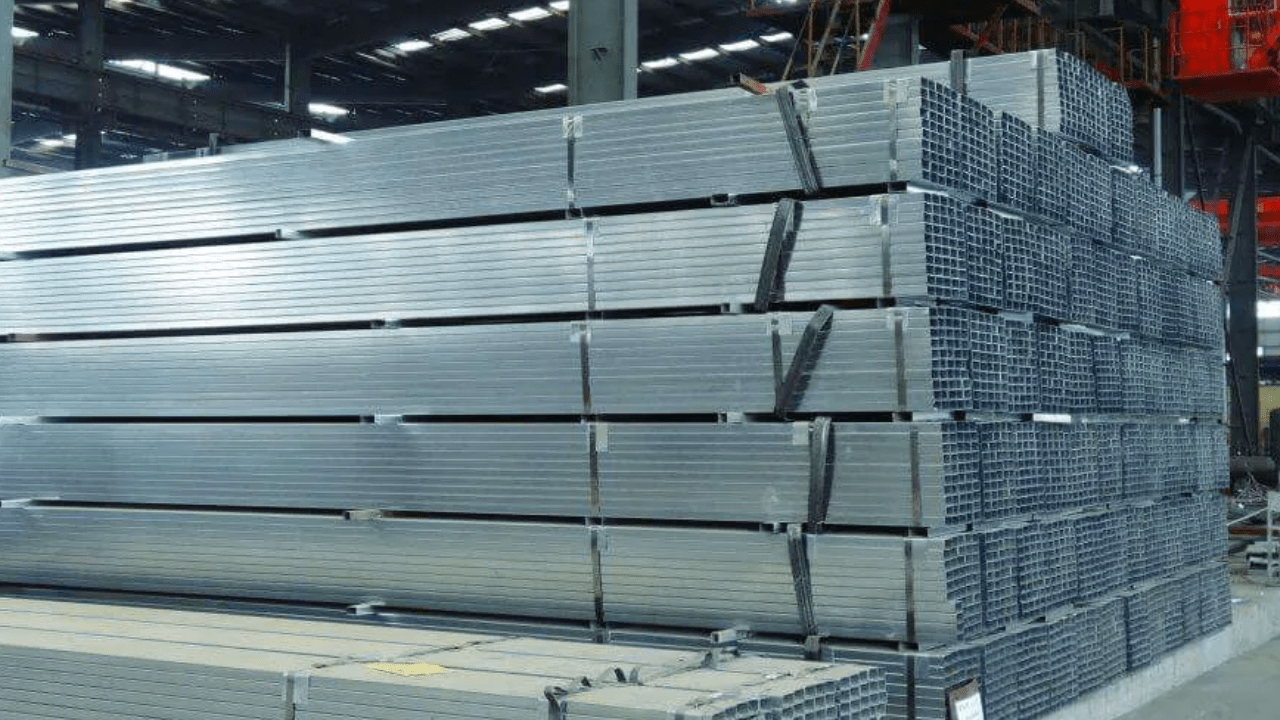

Where are Galvanized Tubes Used?

Galvanized tubes, a key component of steel tubing, are used in construction, infrastructure, and a variety of industrial applications. These tubes are galvanized, which involves applying a protective zinc coating to the steel surface. This coating acts as a strong screen against corrosion and rust, considerably increasing the longevity and endurance of the tubes, particularly in harsh environments.

The galvanization process involves immersing the steel tubes in a bath of molten zinc. This bond not only offers a long-lasting protective layer but also assures a smooth and uniform coating across the whole gal tube surface. Galvanized tubes find widespread use in projects requiring robust and corrosion-resistant materials. The protective zinc layer adds an extra dimension to their structural integrity, making them suitable for outdoor and high-moisture environments.

Applications of Galvanized Tubes in Various Industries

Galvanized tubes, coated with a protective layer of zinc, have become indispensable in a multitude of industries due to their exceptional corrosion resistance and durability. This article explores the diverse applications and advantages of galvanized tubes, highlighting their contributions to construction, infrastructure, agriculture, and manufacturing.

Construction Industry

Galvanized tubes serve an important part of the construction industry, providing durable solutions for a variety of uses. One of the most common applications is in structural components, where corrosion-resistant zinc coatings protect the longevity and integrity of buildings. Galvanized steel tubes are widely used in the construction of buildings, bridges, and other structures because they provide a dependable and long-lasting framework.

Corrosion resistance is especially important in areas with adverse weather conditions. Galvanized tubes are ideal for scaffolding due to their strength, corrosion resistance, and ease of installation. They provide a stable and secure platform for workers engaged in building and maintenance activities. Galvanized tubes are an excellent alternative for railings and guardrails on stairs, balconies, and walkways.

Infrastructure and Outdoor Applications

Galvanized tubes are widely used in infrastructure projects and outdoor applications where exposure to the outdoors necessitates material that can survive extreme conditions. Some significant uses include galvanized steel tubes, which are widely used for fences in residential, commercial, and industrial environments. The zinc coating prevents the tubes from rusting, resulting in a long-lasting and visually pleasing fencing solution.

Galvanized tubes are useful for exterior pole structures such as street lighting poles and traffic signal poles. Corrosion resistance guarantees that these buildings keep their strength and attractiveness throughout time. Galvanized tubes are used for water and gas pipelines, offering a dependable and corrosion-resistant alternative for both subterranean and above-ground installations.

Manufacturing and Fabrication

Galvanized tubes serve an important role in manufacturing and fabrication processes, providing versatility and dependability in a variety of fields. These tubes are used in automotive manufacturing to build exhaust systems, chassis, and other structural components since they are corrosion-resistant and long-lasting. Galvanized tubes are used in industrial machinery to build conveyor systems, frames, and support structures.

Their capacity to endure corrosive environments and provide a strong foundation makes them the favored option. Galvanized tubes’ adaptability to various fabrication procedures improves their use in manufacturing, resulting in the development of long-lasting and durable components. Galvanized tubes, whether used in automotive or industrial machinery production, are critical to achieving durability and performance in fabricated structures and components.

Agricultural Sector

Galvanized tubes provide substantial benefits in agriculture, where equipment is exposed to a variety of environmental conditions. They are utilized in a variety of applications to improve durability and lower maintenance costs. Greenhouses are constructed using galvanized steel tubes. The tubes’ corrosion resistance assures that the structure will last longer, especially in the humid and corrosive climate found in greenhouses.

Galvanized tubes are durable and strong, making them ideal for fencing agricultural holdings and livestock enclosures. Corrosion resistance is vital for defending against moisture and animal waste. Galvanized tubes contribute significantly to the agricultural industry by offering reliable solutions that can withstand exposure to moisture, corrosive elements, and the wear and tear associated with agricultural activities.

Summary

Galvanized tubes have proven to be useful in a variety of industries due to their excellent corrosion resistance, durability, and adaptability. These tubes provide trustworthy solutions for a variety of applications, including building and infrastructure, agriculture, industry, and plumbing. Galvanized tubes are a popular choice for engineers, architects, and manufacturers looking for dependable and long-lasting materials for their projects due to their corrosion resistance, longevity, and low cost.